Digital metallurgy, a different alloy design approach

Safran Tech, the Group’s Research & Technology Center, has conducted extensive research in recent years to help develop tomorrow’s decarbonized and digitized aircraft. Meeting this goal depends on rethinking not only how an airplane works, but also its constituent components and production processes. Here we take a closer look at digital metallurgy, one of the eco-design solutions under consideration.

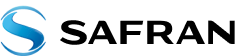

oday, the metallic alloys used in many Safran products are still developed using the old trial and error method. This entails developing and characterizing as many alloys as necessary, using traditional physical, chemical and mechanical methods, and then determining the best composition. But this method takes a lot of time, because analyzing these compositions is a very complex task, and metallurgists have to go through a number of iterations before coming up with the best solution. In digital metallurgy, we use digital modeling and visualization tools to predict the operational performance of proposed metallic alloys. It involves the use of a datasheet in conjunction with thermodynamic evaluation tools.

IMPROVING PRODUCT RELIABILITY AND PERFORMANCE

Digital metallurgy is suited to the development of nickel or titanium-based alloys, and offers a host of advantages. For example, assuming we already have models capable of replacing experimental methods, we can estimate certain key properties for a hundred thousand alloys in just a few days – compared to the trial and error method, which would take at least a day for each alloy. This type of eco-design method for future materials also reduces environmental impact, since it decreases the number of actual physical-chemical tests needed.

Over the last three years, the digital metallurgy method has allowed Safran to design new alloys faster and more robustly, at less expense and better tailored to Group company requirements. Part of a complete product design cycle, it optimizes the design of new metallic alloys to ensure the development of products offering higher performance and reliability.

“This approach allows us to design-in operating and production requirements for these parts very early in the development process.”

RISING TO THE CHALLENGE

For this method to be effective, our design departments have to work very closely with acknowledged Experts in the field. Together, they examine the defined specifications to determine the key criteria expected of the material. The digital metallurgy method does the rest! Olivier Delcourt, head of the Materials & Processes research group at Safran Tech, explains: “This approach, along with advanced modeling tools, results in materials offering a better tradeoff between the different stresses affecting operating parts, especially high temperatures and fatigue corrosion. It also allows us to design-in operating and production requirements for these parts very early in the development process.”

Product candidates

There are a number of possible applications, especially for parts made using additive manufacturing. This includes parts in engine hot sections, such as turbine blades and disks, but also landing gear and engine pylons. The engine parts are considered critical, because they are subject to very high temperatures, requiring equally resistant materials. A number of tests have already been carried out in conjunction with Group companies, including Safran Aircraft Engines and Safran Helicopter Engines. As a result, since 2018, we have already filed for a dozen patents.

More information on additive manufacturing

Read more