Arrano, tomorrow’s helicopter engine

Safran Helicopter Engines designed the new-generation Arrano turboshaft engine for future-generation single-engine helicopters in the 2 to 3-ton class and twin-engine models in the 4 to 6-ton class, like Airbus Helicopters’ new H160. Combining high power and low fuel consumption, the Arrano improves rotorcraft range and payload, meaning it can be used for a wide spectrum of missions. Here’s a closer look at its main features.

All about the Arrano in video

Watch the video

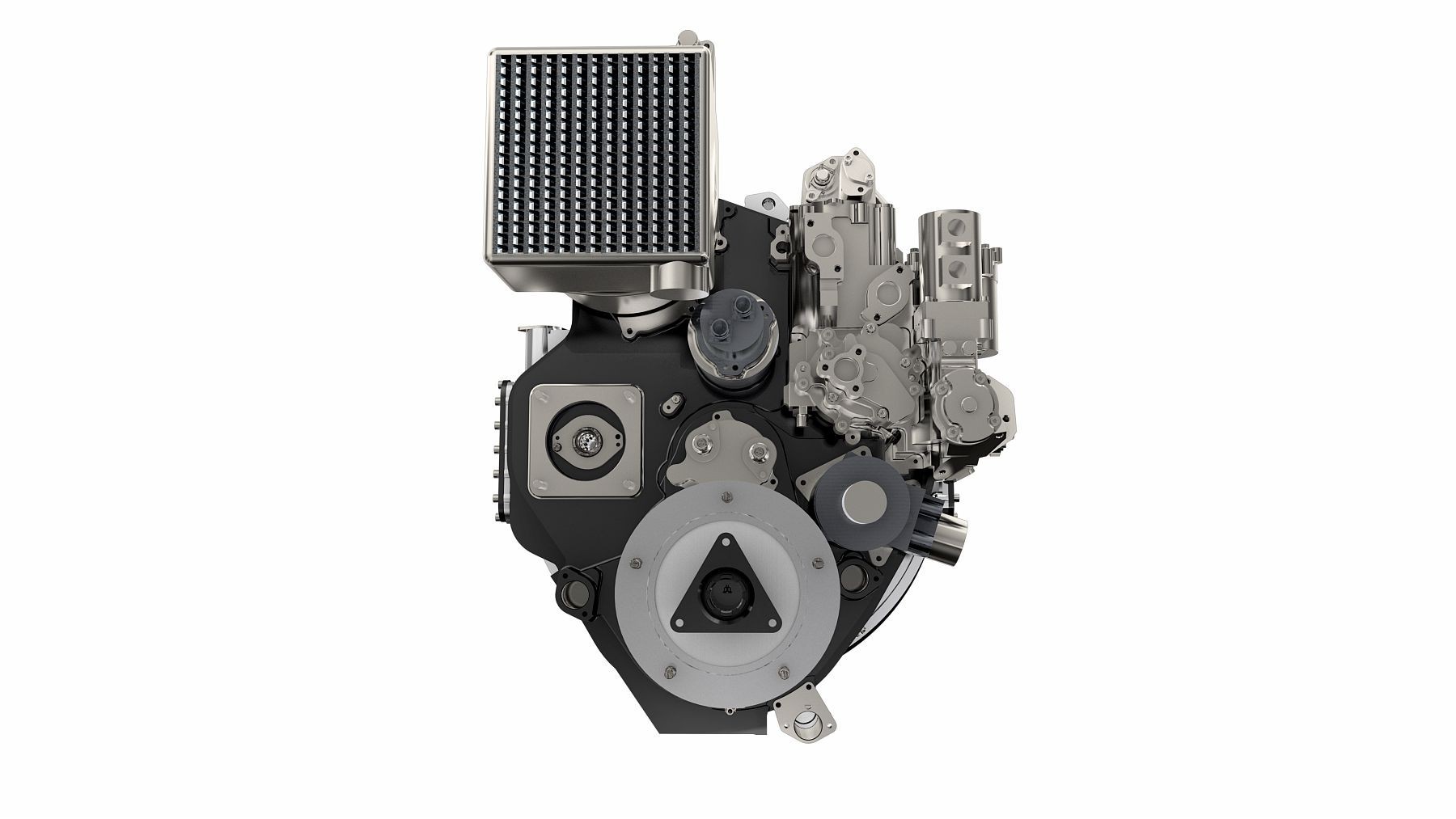

The accessory gearbox with its fuel control unit also includes an integrated oil reservoir and radiator. Located at the front of the engine, this unit allows easy access for quicker maintenance.

An air inlet optimized for flights in very cold conditions.

The compressor case is made of a light alloy to reduce engine weight.

A two-stage centrifugal compressor made of a titanium alloy features good corrosion resistance. It enhances thermodynamic performance and helps reduce CO2 emissions and fuel consumption by 15%.

The swirl type combustion chamber with 3D-printed fuel injectors ensures stable combustion and reduced gas emissions.

The power turbine case, power shaft and exhaust assembly deliver high power with a reduced acoustic signature.

New technologies in a compact package

Arrano marks the first time that Safran Helicopter Engines has used additive manufacturing to make parts subject to high thermal stress. Teams also focused on reducing its environmental footprint, which means that the Arrano can operate on new sustainable aviation fuels (SAF) with no restrictions.