Ramp-up in defense: JIM Compact binoculars see further ahead

With international tensions on the rise and post-pandemic business picking up, demand for defense products is experiencing strong growth, leading to an unprecedented ramp-up. We headed to Poitiers to take a closer look at the production site for our JIM Compact binoculars.

- Photo Report

- Radar

- At a glance

- Perspective

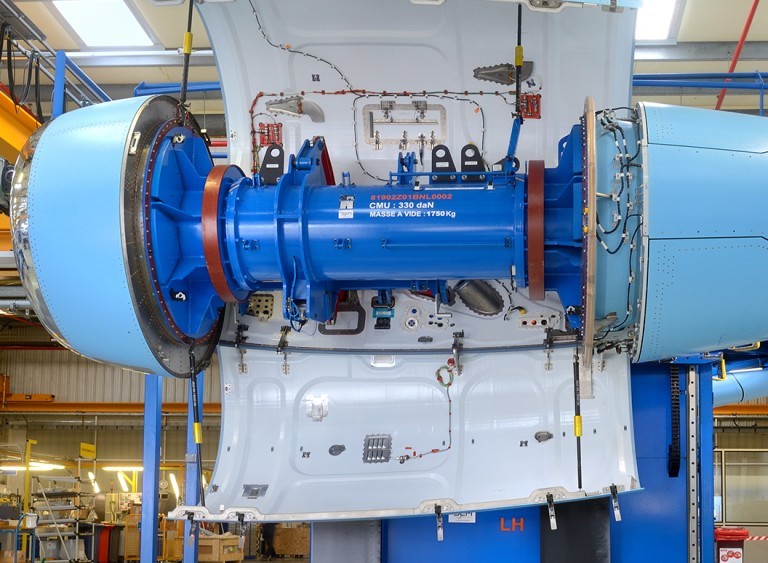

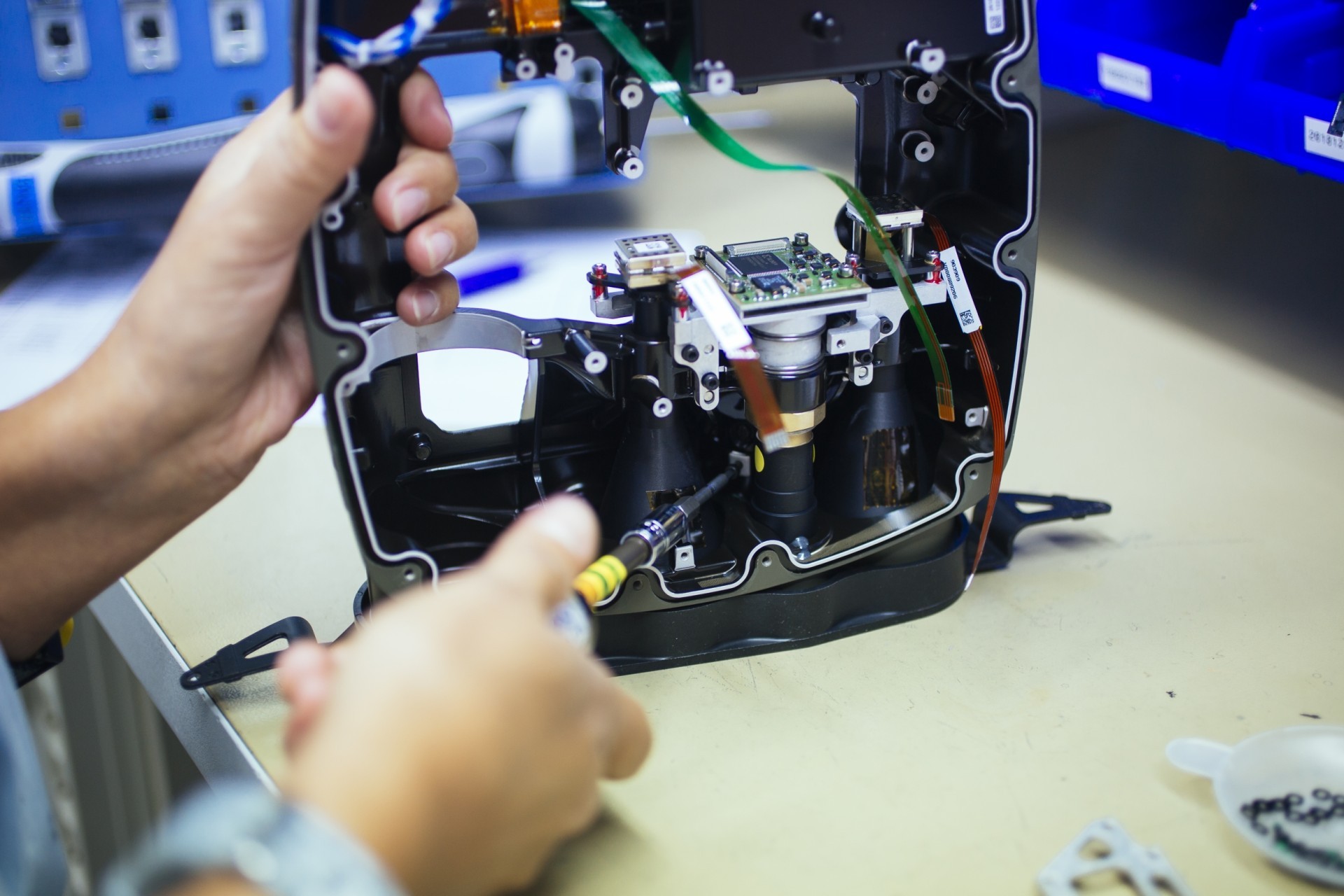

IM Compact multifunction infrared binoculars, made by Safran Electronics & Defense, are a hit in the marketplace. With the recovery underway after two years under pandemic restrictions – allowing our sales staff to meet with customers once again – Safran Electronics & Defense signed two major contracts in late 2021, in the UK and Australia. Another reason for this success is NATO countries rearming in the face of the increasingly tense international situation. If we are to meet this increased demand while continuing to deliver products on time, we need to bolster our JIM Compact production line. It’s a daunting challenge: we delivered 350 of these binoculars in 2021, but this figure will rise to 1,360 in 2022 – 400% growth, which we have to handle despite the crisis in component supply and a very tight labor market.

First challenge: methodology

To meet this challenge, we initiated a JIM Compact ramp-up project, bringing together all job fields at the facilities concerned to implement an efficient and agile organization. The project tackled four main areas: component purchasing, inter-site procurement, capacity aspects on the production line at Poitiers, and technical aspects to achieve zero defects. Black Belts were brought into the project as well to oversee the process each step of the way.

Given these conditions, the production line in Poitiers upgraded its standards to earn the FlexSensiel label. The organization was also enhanced to reduce work-in-process and production cycles. All of these efforts are designed to achieve zero defects. While the label is only a small step on a long road for the Production department, it supports continuous improvement over the long haul. Out of the 1,360 deliveries projected in 2022, about 800 are targeted for the last quarter. In short, a very busy end of the year, due to the exponential nature of the ramp-up.

“JIM Compact is a perfect market fit. But we have to get our subcontractors to buy into the ramp-up and also increase staffing in the production department.”

key figures

- 350

JIM Compacts delivered in 2021

- 1,360

Deliveries expected in 2022

Second challenge: elementary particles

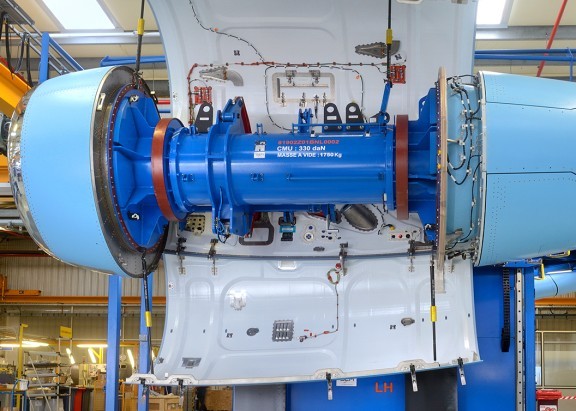

The ramp-up is taking shape in Poitiers, but it involves Safran Electronics & Defense’s entire supply chain. With demand for electronic components and raw materials spiraling, the supply chain is more than ever a key to success.

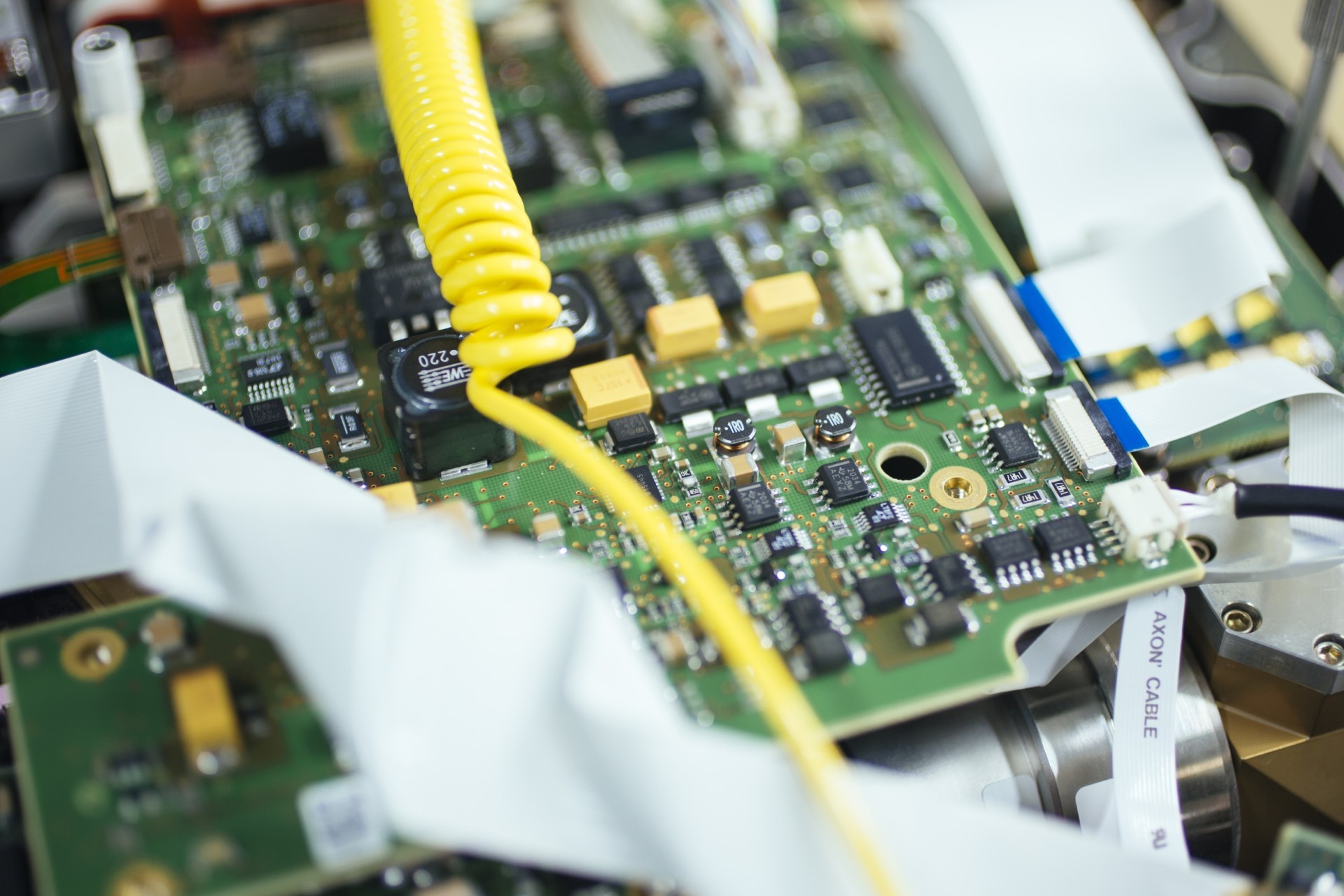

Firstly, this is reflected in procurement between the company’s different facilities. JIM Compact binoculars are assembled in Poitiers, but the integrated circuit boards come from Fougères and some of the mechanical subassemblies from Montluçon. Because of this interdependence, everything has to be carefully coordinated to ramp up in synch. Secondly, subcontractors play a vital role in ensuring the success of the ramp-up. For instance, a procurement plan was set up, with our teams contacting suppliers to evaluate their ability to increase production, and they worked hand in hand to improve methods. Warehouses were also reorganized, and this operation should be completed before the shutdown for summer vacation in August. Transport will also be augmented, for both reception of merchandise and shipping to the workshops, as well as for deliveries of finished products.

Third challenge: ramping up the workforce

Today, Poitiers has 45 people working on JIM Compact. But to meet our production targets, the plant will have to add 40 more by the summer. This is a huge challenge for everybody at the plant, in terms of both human resources and training, and all within a very tight timeframe. In the final analysis, the HR ramp-up in Poitiers is a challenge on the organizational, technical and human level – one that the teams in place will rise to successfully!

“This is obviously a huge challenge, but we’re excited about tackling it!”

LEARN MORE ABOUT JIM COMPACT BINOCULAR SYSTEM

Learn More