ADDITIVE MANUFACTURING FACILITATES M88 RAMP-UP

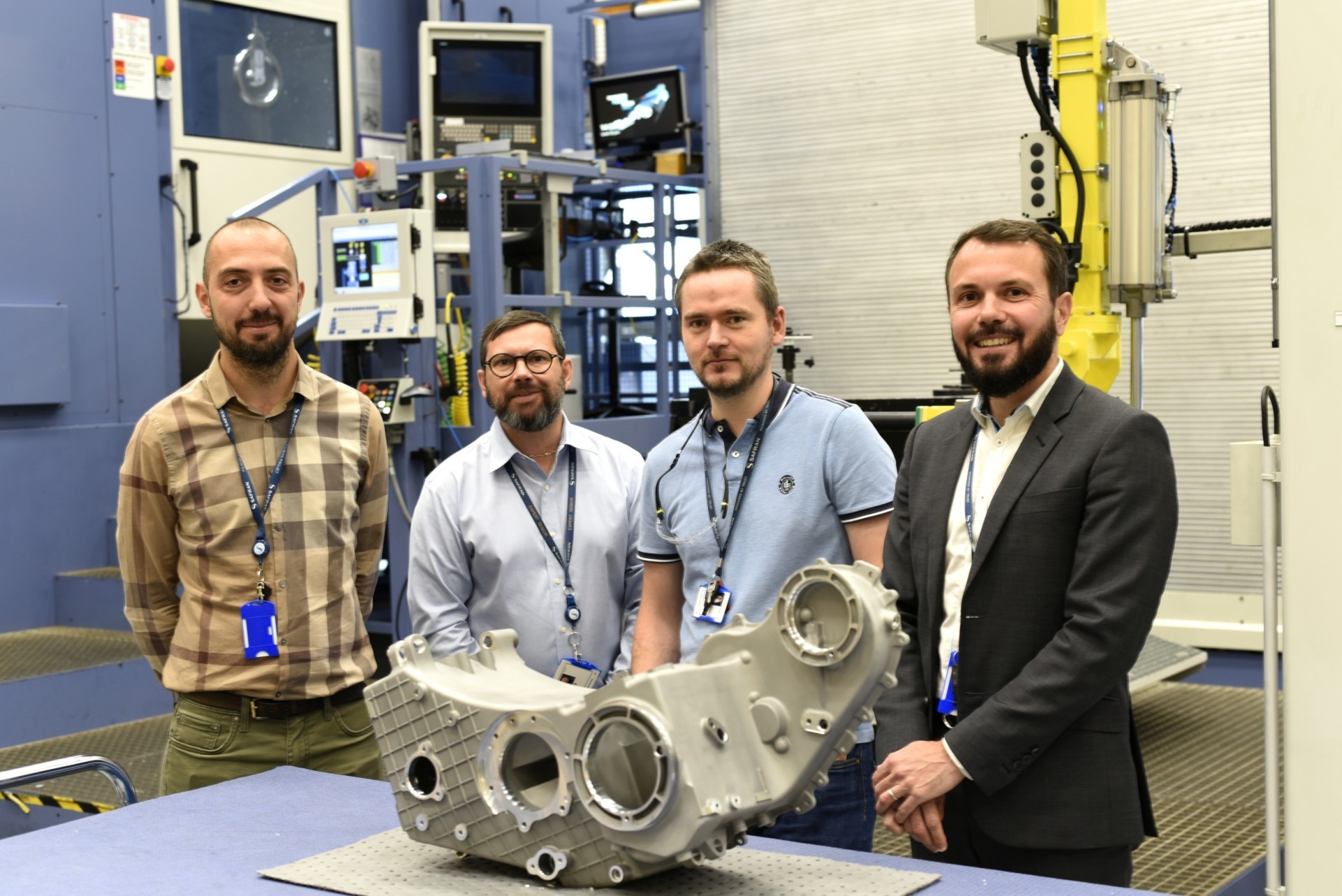

On March 1, 2022, the Additive Manufacturing team at Safran Transmission Systems unveiled their latest achievement: the rear case for the accessory gearbox on the M88 engine powering the Rafale fighter.

- Snapshots

- Success

- Photo Report

- At a glance

- Discovery

This project was implemented in conjunction with the Safran Additive Manufacturing Campus (SAMC) and Lisi Aerospace Additive Manufacturing (LAAM) to keep pace with the ramp-up in Rafale deliveries.

Using additive manufacturing to meet an ambitious goal

Unlike conventional processes, additive manufacturing (AM) makes parts by building them up one thin layer at a time, using metallic powder melted by a laser beam.

Also known as 3D printing, additive manufacturing offers a host of advantages: flexibility, weight savings, less need for raw materials and the ability to make complex parts at lower cost, as well as parts that can’t be made with conventional technologies. In short, it’s a revolution!

Safran Transmission Systems, the world’s leading supplier of aircraft mechanical power transmissions, launched this AM project for a rear case on the M88 to support the ramp-up in Rafale production.

A complex M88 part

The case for the accessory gearbox on the M88 engine was originally designed for production using the lost-wax casting method – a process that precisely casts a metallic object from a wax model. “Our first challenge was to prove that it’s possible to 3D print this case without major modifications,” notes Pierre Vanraet, R&D engineer.

The case is a large aluminum part, measuring 720 x 270 x 425 mm. It also has technical features that mean most alternative methods can’t be used. However, additive manufacturing works here, and it retains the current design without significantly adding weight.

The case was produced using the selective laser melting (SLM) process with a special aluminum alloy to improve its mechanical qualities, built up in layers of only 50 microns.

Behind the ramp-up strategy

“We still have to meet a number of challenges to earn the qualification needed for the 3D-printed case to enter service,” notes Pierre Vanraet. “Along with Safran Aircraft Engines and SAMC, we defined a roadmap to prepare for the ramp-up, with production increasing over 250% by 2024.”

Several R&T projects are under way to improve mechanical characteristics and surface state, while decreasing the cost of cases produced using this process, to be more competitive with foundries. The qualification process will come next, so the company can start actual production.

“Making cases with additive manufacturing is a new process at Safran,” notes Pierre. “Now we have to establish the rules and procedures to be used for future design projects.”

Rafale’s M88 engine passes milestone of one million flight-hours

This milestone will undoubtedly be followed by many more. Building on the experience logged with French armed forces, the M88 has sparked further interest in export markets, including initial customers Egypt, the United Arab Emirates, Qatar and India, and new users Greece, Croatia and Indonesia. In the years ahead, these latest orders will generate thousands more flight hours and more work at Safran.

M88 - Proven performance and reliability

Read more