Low carbon: Asia leads the way

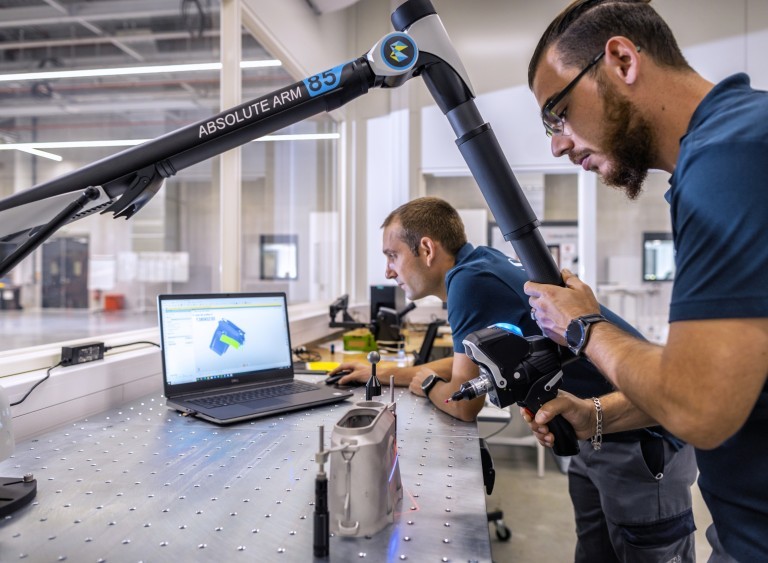

Safran has a long-standing presence in the Asia Pacific region, with no fewer than thirty sites currently. Since the launch of our Low Carbon Plan in 2018, employees across the region have rolled out a host of initiatives to achieve the Group’s ambitious goal of cutting CO2 emissions by 30% by 2025.

- Interview

- Photo Report

- Perspective

- At a glance

Solar projects

“Reducing energy consumption is one of the main levers available,” says Alexis Tran, head of indirect purchasing for Asia Pacific. “This can involve, for example, installing solar panels on factory and parking lot rooftops.” At the Suzhou site, which is home to several Safran companies, Safran Aircraft Engines and Safran Landing Systems signed a joint contract in November 2021 with the same supplier to cover an area of 32,000 square meters (345,600 sq. ft) with photovoltaic (PV) panels. The installation will provide up to 3 MWh of electricity, equivalent to 6-10% of the site’s total requirements. Also planned is solar lighting on the outside of buildings and along access roads and electric vehicle charging stations. Thanks to these initiatives, roughly 1,700 metric tons of CO2 will be saved each year.

Other solar projects have come online in Thailand (Safran Cabin Lamphun), Singapore (Safran Landing Systems Services Singapore, Safran Helicopter Engines Asia, Safran Electronics & Defense Services Asia, Safran Aerosystems Services Asia) and in Malaysia, where the Safran Landing Systems plant in Sendayan installed solar panels on its parking lots in 2019 and now intends to do the same across the entire factory roof.

More efficient building management

Safran facilities are also tapping into energy savings inside buildings. In Suzhou, conventional lightbulbs have been replaced by LEDs, while the site’s two compressors have given way to a centralized, more energy-efficient installation. Other upgrades include a new, more efficient air conditioning filtration system and air cooling system. “A sensor-based energy management system allows us to monitor energy consumption by our production facilities in real time,” adds Alexis Tran. “This helps raise awareness among production staff of best practices, like switching off certain machines over the weekend or over holiday periods.”

Meanwhile, newly installed LEDs will allow Safran Helicopter Engines Asia in Singapore to achieve savings of 9 metric tons of CO2 emissions a year, along with an additional 66 tons thanks to solar panels. Combined, this is equivalent to the electricity consumption of a 38-floor building. In another initiative in Singapore, Safran Electronics & Defense Services Asia has compartmentalized production shops to ensure optimal use of the air conditioning system, limited to 25°C. Throughout the plant, employees can report malfunctions by scanning a QR code to help speed up repairs.

- 1,000 metric tons

That’s the amount of CO2 emissions Safran Seats and Safran Aero Boosters avoided in their supply chain flows in 2021 by diversifying transport modes and consolidating shipments.

More eco-friendly transport

Transportation is another key step on our path to decarbonization. Alexis Tran explains: “By combining air, land and maritime transport, Safran Landing Systems Suzhou cut C02 emissions from equipment shipments by 80% between 2019 and 2020. Safran Aircraft Engines Suzhou has improved transport flows and saved close to 680 metric tons of C02 a year by buying its containers in China rather than Europe.”

Another top priority is encouraging greener work-related travel. One-third of the shuttle buses that serve the Suzhou site are now electric, saving 126 metric tons of C02 per year. Employees are also encouraged to play their part in decarbonizing sites by adopting more eco-friendly habits, like switching off lights that aren’t needed, closing windows when the air conditioning is working – and switching it off when they leave. At Safran Electronics & Defense Services Asia, regular staff awareness campaigns help share these simple but effective tips and an annual in-house innovation contest includes a low carbon category.

Carbon-cutting efforts also include the supply chain, where the focus is on integrating low carbon criteria when selecting suppliers and prioritizing local supplies. For example, 60% of indirect purchases by Suzhou are made in China. As well as reducing carbon emissions, this strategy translates into cost savings and faster deliveries. In short, a virtuous circle that underscores the relevance of Safran’s Low Carbon Plan.

More sustainable new buildings

All new Safran facilities are built according to sustainable design standards to meet the Group’s low-carbon objectives. Safran Aircraft Engines’ new plant in Guiyang, China, for instance, is designed to minimize energy usage and thus reduce its carbon footprint. The roof features large windows to let in natural light for the production shops. LED light units with motion sensors have been fitted. High-performance insulation materials have been installed and solar heating is used for the restrooms. The result is a 20% reduction in carbon emissions.

360° approach

Our environmental responsibility is not just about reducing our carbon footprint from energy consumption, as the Group’s sites in Asia are showing. They are equally committed to saving water (by fitting tap aerators), reducing waste (with reusable cutting tools) and encouraging reuse (adapting storage racks for other purposes).