RISE: shaping the future of commercial aviation

Safran’s commitment to achieving net-zero carbon emissions by 2050 calls for a technological revolution. At stake: a single-aisle commercial jet with new, ultra-efficient engines that would enter service by 2035. This ambitious goal is being pursued through CFM’s RISE program, to which all Safran companies are contributing.

- ELECTRIFICATION

- E-TAXIING

- INTERIORS

- At a glance

- Zoom

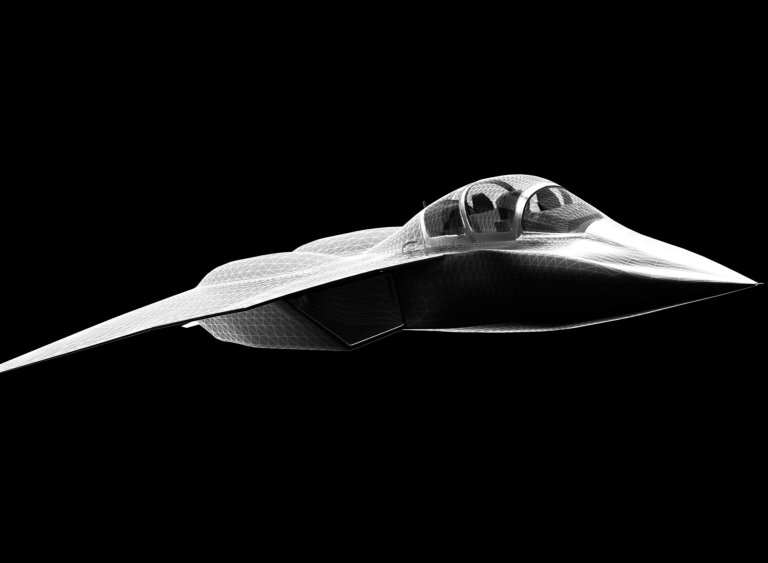

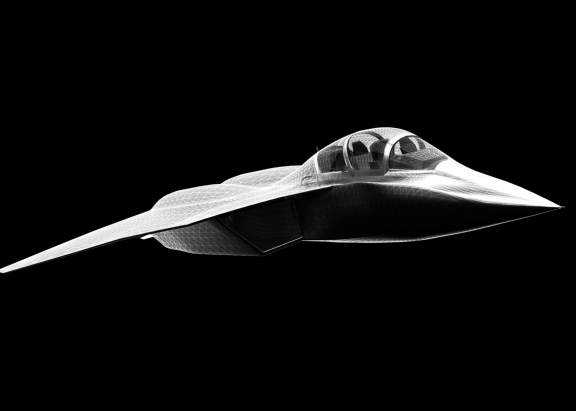

Since CFM launched its RISE (Revolutionary Innovation for Sustainable Engines) technology demonstration program in June 2021, some key milestones have already been reached. These include the cooperation agreement signed between CFM International and Airbus in 2022 to build a flight-test demonstrator based on an open-fan architecture (i.e. without the usual shroud) with a span of four meters. The twofold objective is for this ground-breaking architecture to cut fuel burn by 20% versus the current LEAP engine by 2035, and to be fully compatible with sustainable aviation fuels in order to further reduce CO2 emissions. The engine’s ability to run on hydrogen is also one of the avenues being explored with Airbus, which is aiming to fly a zero-emissions demonstrator before the end of this decade.

The program is making good progress, as Delphine Dijoud, RISE technical manager, explains: “We’ve defined the architecture and the technology maturation plan with our partner GE Aerospace. The first prototype parts are also under test. The first aerodynamic tests on the high-speed turbine were completed last year and are now starting on the fan. The next step is to validate the preliminary design of the engine demonstrator this year for ground testing in 2025. “We’ll also continue testing this year to mature the underlying technologies for the first demonstrator, and then start work on a hybrid electric layout.”

These advances reflect the efforts of all aviation stakeholders, from aircraft manufacturers to suppliers, academia, and government agencies under European — notably Clean Aviation — and national R&T programs. “A one-fifth-scale model of the open fan and its guide vanes is undergoing wind-tunnel testing at ONERA, the French aerospace research agency, to study acoustic and aerodynamic performance,” adds Dijoud. “The next step, working with Airbus, will be to mount the engine on the pylon and wing to study its integration on the aircraft. Given the engine’s size, this is a key to understanding all the physical and acoustic phenomena at play in readiness for flight demonstrations.”

Delphine Dijoud

“The challenges involved are both technological and human. All departments at Safran are involved in the demonstration plan, from design and manufacturing, to assembly and testing. More than 800 people are already working on the program, and that’s expected to exceed 1,000 this year.

All the technological expertise we acquire through RISE will endorse our ambition to be a complete engine manufacturer,” says Delphine Dijoud. “It’s an exciting opportunity to be working on this program to find a propulsion solution to meet the climate challenge. For that, we need robust technologies that will serve us in the future and be easier to integrate, whatever architecture aircraft manufacturers finally choose.”

All the technological expertise we acquire through RISE is going to drive our ambition to be a complete engine manufacturer.

Abirami Remigius

“I’m working on the design and fabrication of the fan and LP turbine modules, combining the skills I acquired from the SAM146, Silvercrest and LEAP programs. My role is to coordinate the design engineering and methods teams at the compressors, chambers and structures center of excellence to advance the technology readiness level (TRL) of parts. Additive manufacturing is one of the key processes on RISE, and Safran Aircraft Engines teams are working with their counterparts at Safran Additive Manufacturing to scale up fabrication of several complex parts made until now by conventional casting. Our goal is to be making parts more than one meter in diameter within five years. And for a large portion of RISE parts we’re adopting digital process simulations to optimize the design. All the work we do between now and 2030 is vital to defining industry future needs. That means we have to structure and optimize our industrial processes. It’s really exciting to be working on this future-looking product, and developing high-level skills while keeping a close eye on environmental aspects.”

It’s really exciting to be working on this future-looking product, and developing high-level skills while keeping a close eye on environmental aspects.

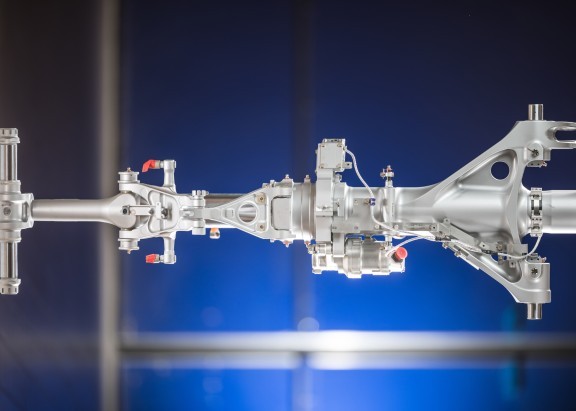

Clément Cottet

“I’m in charge of integrating the fan root and variable pitch system, which marks a complete break with previous-generation engines. I’m also involved on the engine nose cone developed with Safran Nacelles. To innovate, we’re leveraging lessons learned and thinking outside the box to design a high-performance system. Work is underway in partnership with GE and other Safran companies to consider alternatives to conventional turboprops. At Safran Aircraft Engines, we’re building on the experience acquired on the open rotor tested successfully in Istres in 2017. And we’re talking to aircraft manufacturers, notably about the thrust reverser, to learn what they want. I’m proud to be working on the next generation of engines to advance aviation and secure Safran’s future. It’s great to be contributing to this engineering and environmental challenge…”

It’s great to be contributing to this engineering and environmental challenge…

Who does what

Several Safran entities are working on the RISE demonstration plan in partnership with CFM:

- 1

Safran Aircraft Engines is involved on the engine demonstrator.

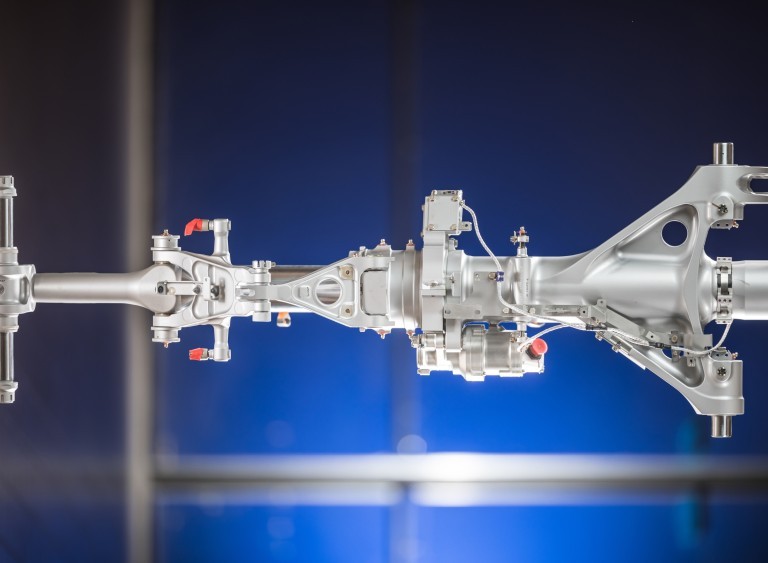

- 2

Safran Transmission Systems is working on the reduction gearbox and power transmission.

- 3

Safran Additive Manufacturing Campus is involved with Additive Manufacturing and experimental casting.

- 4

Safran Aerosystems is playing a role in de-icing and several engine accessories like the pitch setting servovalve.

- 5

Safran Tech is supporting Safran Aircraft Engines on coatings, high-temperature metals and ceramics, optimizing metal parts for the reduction gearboxes, weight savings with composites, and process modeling.

- 6

Safran Electrical & Power is working on a hybrid electric layout for the engine, developing electric machines wiring harnesses, converters, connectors, and distribution components like contactors.

- 7

Safran Aero Boosters is designing and fabricating a mid-fan, booster, exchangers and lubrication system components.

- 8

Safran Nacelles is devising a front and rear composite and metal aerodynamic structure for the fans, the nozzle, certain rotating parts, and acoustic surfaces.

- 9

Safran Landing Systems is working on the hydraulic pump for the fan pitch actuation system (FPAS).

RISE: high voltage and power

With the advent of RISE and hybrid electric designs, new engine functions are going to be electrified to increase propulsive efficiency. Other aircraft and engine systems will also be powered through high-voltage wiring. Safran Electrical & Power is ready for the challenge of supplying electric machines, harnesses, converters, connectors, and distribution components like contactors. Technologies in development on the ENGINeUSTM, GENeUSTM, and GENeUSGRIDTM series, as well as harnesses and components, are good candidates. Some of these products have already completed flight testing, but proving their robustness and reliability remains a major challenge, particularly at RISE’s planned operating altitudes and temperatures. The program also includes of course ground and flight demonstrators to help mature these technologies.

WORKSHOP - 3 FEBRUARY 2023

"Electric Hybridization" with teams from Safran Aircraft Engines and Safran Electrical & Power.

Radar podcast : on the way to carbon-free aviation with RISE

Listen to the podcast