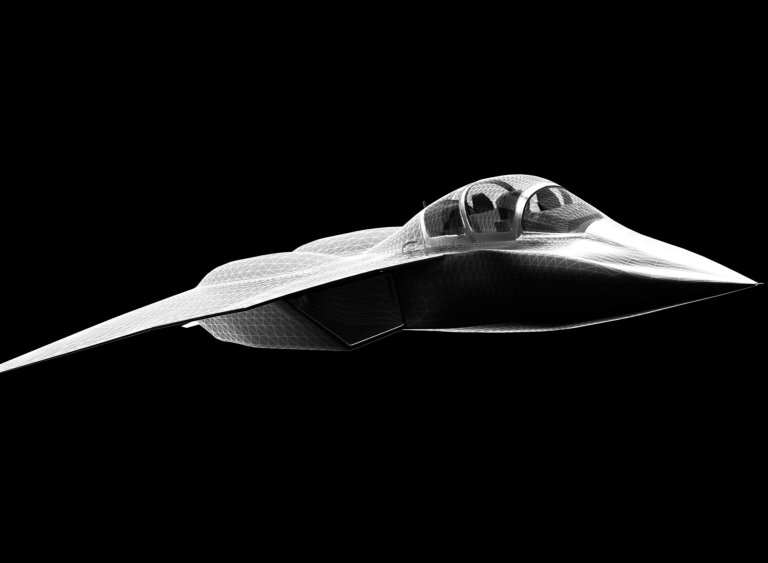

E-taxi cuts CO2 emissions

Safran Landing Systems’ e-taxi system enables aircraft to taxi under their own electrical power, reducing CO2 and NOx emissions by up to 61% and 51%, respectively, during this phase.

- ELECTRIFICATION

- INTERIORS

- At a glance

- Zoom

Taxiing is the phase during which an aircraft rolls out to the runway for takeoff and back after landing. Until now, aircraft have taxied using their main engines, burning fuel and emitting CO2 for 20 to 30(1) minutes on a short- or medium-haul flight at a very busy airport like Paris Roissy-Charles-de-Gaulle. Essentially, aircraft engines are not really designed to perform this function.

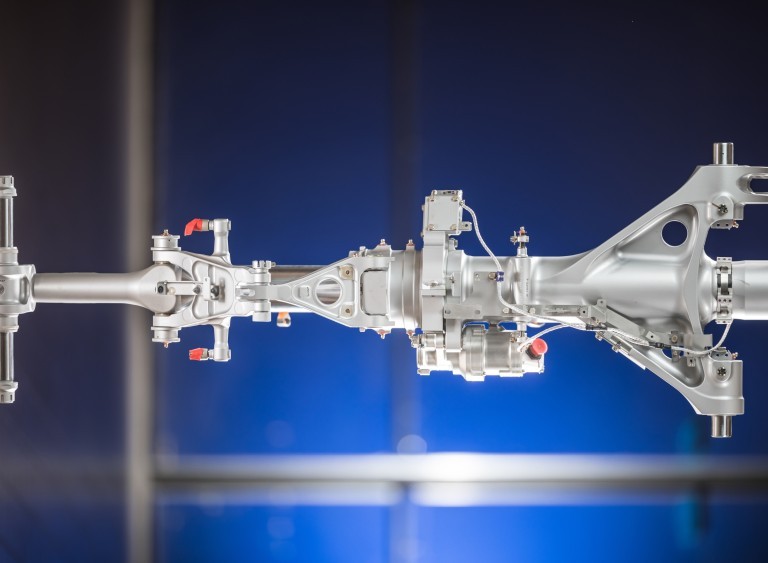

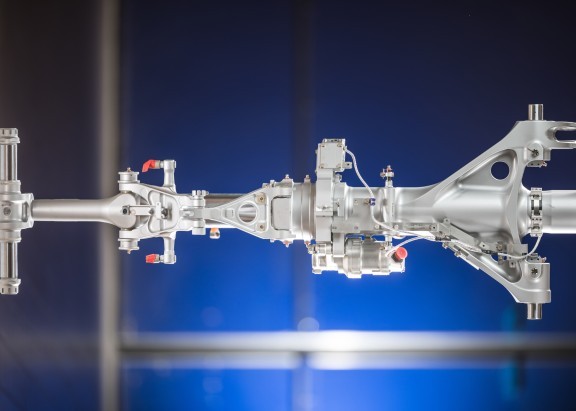

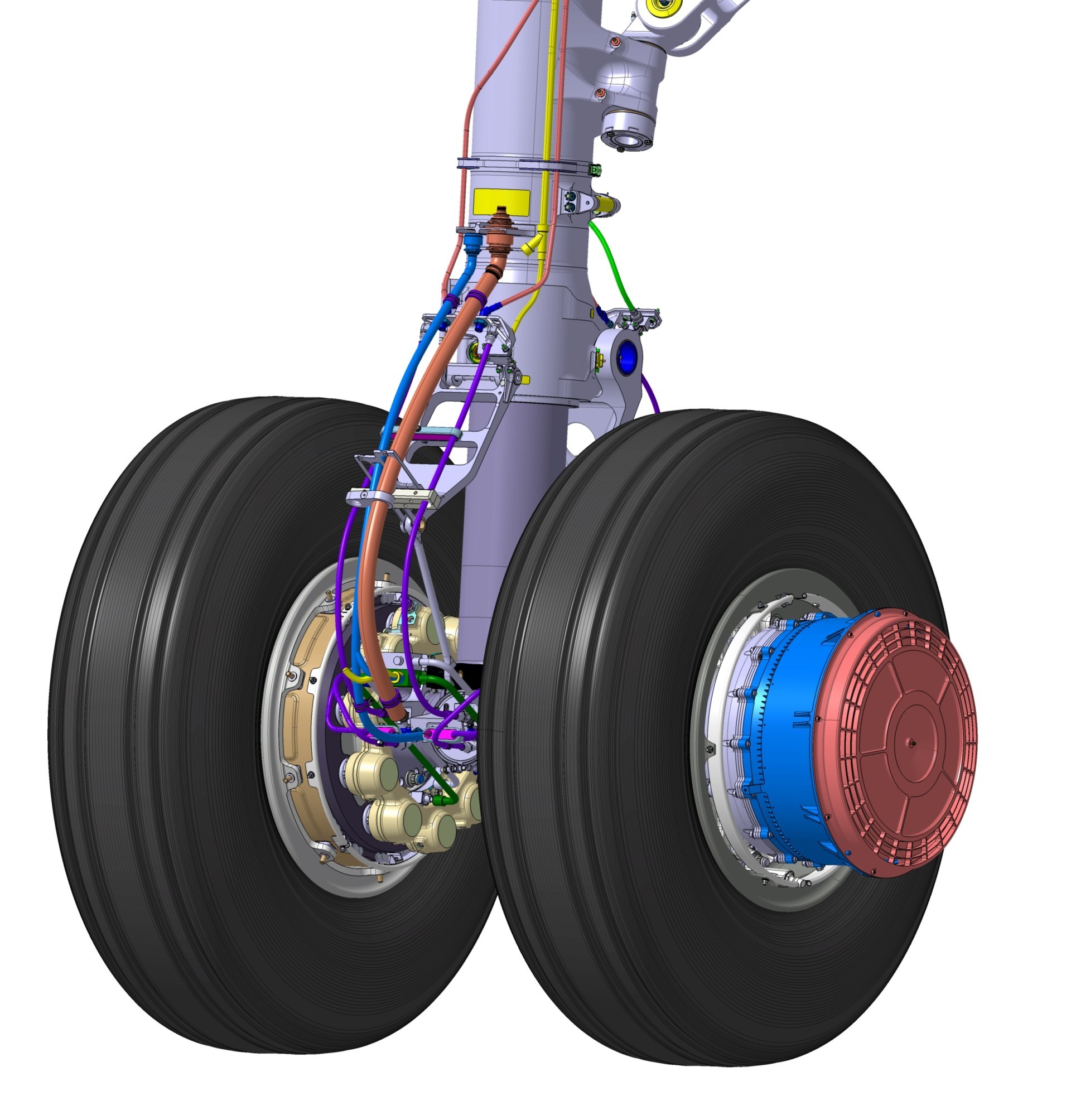

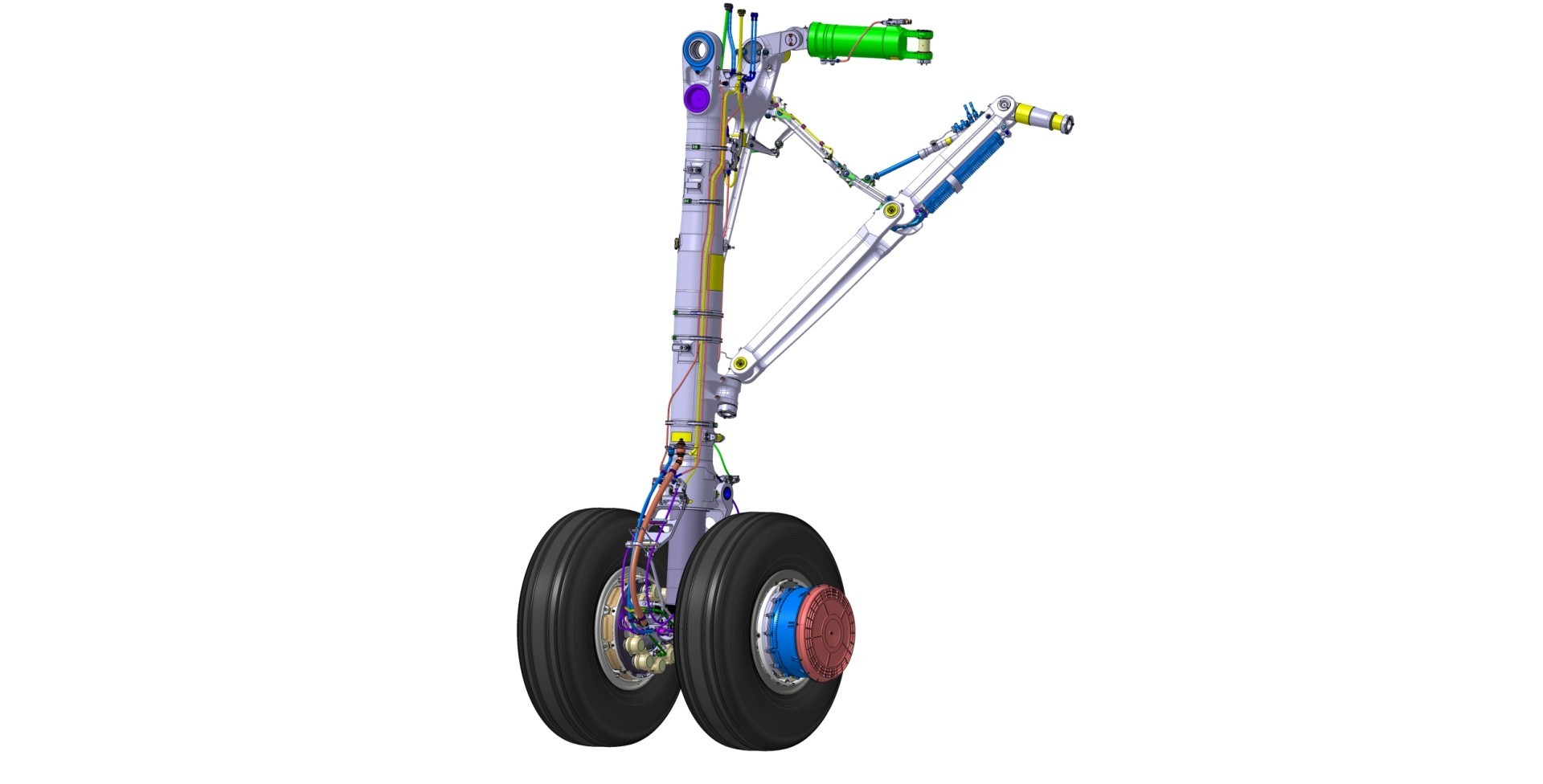

Enter the e-taxi system, which uses electric motors driven by the auxiliary power unit (APU) to set the landing gear wheels in motion. Located in the aircraft’s tail, the APU generates electrical and hydraulic power, burning a lot less jet fuel than the main engines. The main advantage of the e-taxi system is that it delivers fuel savings of up to 4% for flights up to 1,000 nautical miles, and greatly reduces carbon emissions on the ground, bringing operators both environmental and financial benefits.

According to Jean-Philippe Vaslin, R&T Program Director and Deputy Head of R&T at Safran Landing Systems, the e-taxi concept is simple but very hard to implement. It has to operate in a highly constrained environment, entails multiple technology building blocks, and must satisfy aircraft safety and reliability requirements.

Ongoing work on the design and to mature the technology must seek to devise a system for the next generation of short- and medium-haul aircraft.

The system is designed to match airlines’ operational needs and reduce weight. To meet our customers’ requirements, we’ve also developed a system that’s easy to remove and replace. “Some operators fly different routes throughout the year. They may want to reconfigure their aircraft and take out the e-taxi actuators to suit their needs, so we’ve limited the landing gear interfaces,” explains Kyle Schmidt, Head of R&T at Safran Landing Systems.

Another key benefit of the system is noise reduction. Because the aircraft’s main engines are not running during taxiing, it makes a lot less noise. This is a big plus for airports increasingly looking to limit noise propagation beyond the runway areas. The system also reduces the risk of incidents during ground maneuvers and makes parking much easier.

“The market’s ripe for e-taxi systems: indeed, some airlines wish our system was available now,” notes Kyle Schmidt. “But it’s hard to retrofit an aircraft for which it wasn’t originally designed. It’s doable, but technically very challenging.” Safran Landing Systems teams regularly meet with airline customers to present available technologies, and our e-taxi system is high on the list.

Fast fact

Other Safran companies involved in the e-taxi project are Safran Electronics & Defense, Safran Electrical & Power including Safran Electrical Components, Safran Transmission Systems, Safran Ventilation Systems and Safran Tech.

Discover taxiing in video

Watch the video

(1) Counting all phases before takeoff and after landing.