Take a seat in the cabin of the future!

Imagine yourself boarding a plane in 15 years. What will the interior look like? One watchword, already a priority today, is sustainability. From slimmed-down seats to eco-designed trolleys and overhead bins, these are some of the environmentally-friendly features you’ll see in the cabin of tomorrow.

- ELECTRIFICATION

- E-TAXIING

- At a glance

- Zoom

Think “cabin of the future,” think eco-responsible. And the future starts right here. Saran Cabin is ahead of the curve. It has launched the Green Innovation Program (GRIP), which ties together all projects designing lighter, more eco-conscious equipment. The goal: reduce the environmental impact of its products.

The Sustainable Product Architecture (SUPRA) project is part of this initiative: it involves redesigning product architectures with new lighter and more environmentally friendly materials.

To do this, the entire lifecycle of its equipment has been analyzed in a large-scale study that has identified the products with the highest environmental impact in order to seek new biosourced, recycled and reusable materials. A demonstrator will be ready in June, which will help support dialogue with customers on this project.

So, the result will be environmentally friendly products that still offer the highest standards of quality. Soon, for example, the overhead bins where you stow your jacket and hand luggage will be eco-designed.

The goal of all these projects is do more with less…

More with less is also the object of Gray Water ReUse, launched by Safran Cabin as part of the GRIP program. Currently at the testing phase, this system filters the wastewater from aircraft sinks and reuses it for toilet flushing, resulting in water savings of up to 25%.

Safran Cabin engineers had to solve a host of technical challenges: not least make the system as small and light as possible and ensure faultless filtration.

The promising Grey Water ReUse project is backed by the prestigious California Institute of Technology — winner of the Gates Foundation Reinvent the Toilet Challenge.

We need to think differently about our use of materials, energy and resources…

Environmental stewardship is also a priority when it comes to seats…

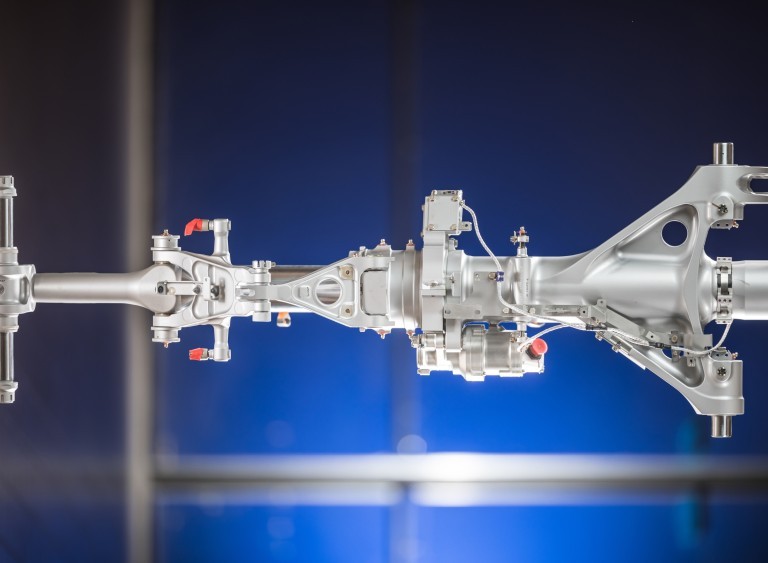

Safran Seats plans a 20% weight saving across all its products by the end of the decade. To achieve this, it will use several levers.

Last fall, the company ran an in-house contest to unveil a prototype business-class seat that’s 15 to 20% lighter than current products. The initiative spawned over 100 ideas, including alternative seat architectures, which aim to make the skeleton as light as possible.

Engineers, designers and product architects are now tasked of developing the most promising ideas, so they can be tested with airlines, before integrating the most mature approaches into its range of seat products.

We’ve launched a plan to mature the technical building blocks and strategic projects needed to develop more eco-responsible products, in line with Safran’s decarbonization goals…

Safran Seats has also embarked on two strategically important projects funded by the French Civil Aviation Authority (DGAC) to make its products lighter. The first, TERRA PRETA, aims to make seat parts from offcuts of carbon fiber — an especially light material — initially produced by Safran Aero Composite for LEAP fan blades. The first prototypes will be ready this year. The second project, FAMOUS, aims to deploy industrial-grade fusion 3D printing of various parts. Here again, the object is to produce lighter seats. The first parts will also be made this year.