Fiber sensing: Safran at the forefront

Fiberoptic data acquisition or “fiber sensing” — currently being explored by Safran Tech and Safran Data Systems — could become a crucial technology for the Group. Here’s where we’re at with our research…

- ELECTRIFICATION

- E-TAXIING

- INTERIORS

- At a glance

- Zoom

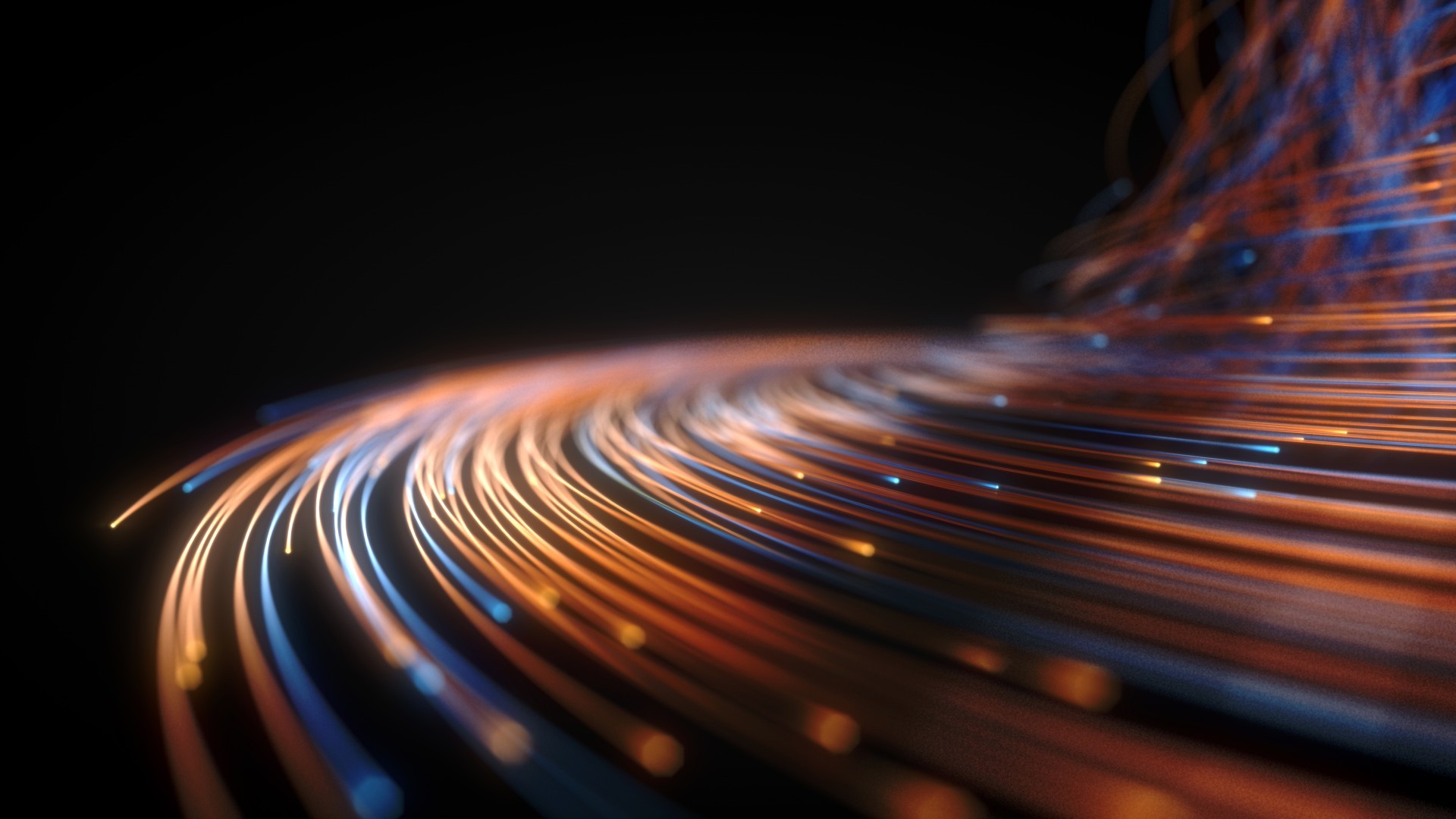

Well known for its applications in the telecoms sector, fiberoptics, or optical fiber, opens huge prospects for progress and innovation in aerospace because of its robustness and immunity to electromagnetic radiation. What’s more, it can be transformed to serve as a temperature sensor or to measure stresses such as pressure and vibration. “This technology, which is mature in the civil engineering industry, is also proving operationally promising for certain types of ground tests,” says Ghislain Guerrero, business development and innovation director at Safran Data Systems. He continues: “Its use in flight will allow continuous real-time analysis of what’s happening in the most complex areas of an aircraft — and with minimal intrusiveness, unlike electrical sensors today. For example, we could build it directly into composite parts. However, this solution still presents difficulties, which we’re working to overcome, such as resistance to vibration, shock and temperature variations in the optronic parts connected to the fiber.”

Winning trio

Since January 2020, Safran Tech — via its S3AR laboratory (Safran Sensing Systems Application and Research) — has been conducting research in close collaboration with Safran Data Systems and a German startup called FiSens. This unique group of three aims to demonstrate the feasibility and reliability of these fiberoptic sensors and assemble the technological building blocks needed for their effective introduction.

Our research is of real interest to all Safran companies because of its transversal applicability…

Fuel level measurement, detection of deviations in wheel shape, fire detection in the nacelles, measurement of stresses and temperatures of mechanical parts — the list of potential applications will likely be long. “Our research is of real interest to all Safran companies because of its transversal applicability,” continues Ghislain Guerrero. He concludes: “We’re pushing ahead in agile mode, working as closely as possible to real-life conditions and operating environments. In July 2022, we conducted our first flight test on the SAE test plane, which taught us a lot. We’ll continue to bring this technology to maturity over the next few years with the goal of series production by 2030.”

To be continued…

Find out more about fiber optics at Safran Tech

Read the article

What is fiberoptic?

An optical fiber is a glass or plastic wire typically sheathed in a first reflective layer and a second cladding layer or “protective” armor. When light enters an optical fiber at one of its ends, it’s subject to continuous internal reflections down the length of the wire, making it a light conductor. Since light can be coded with information, the cable can be used to transmit data. Developed in the 1970s in the telecoms sector, this technology is especially useful for the aerospace industry because it’s robust and resistant to high temperatures, which means real-time information can be transmitted continuously.

Discover in video the profession of research engineer in fiber optic sensors

Watch the video