European defense: FCAS takes off!

On December 15, 2022, the French, German and Spanish governments announced the contract award to Dassault Aviation, Airbus Defense & Space, Indra and EUMET (European Military Engine Team) for the next phase of the Future Combat Air System (FCAS).

- ELECTRIFICATION

- E-TAXIING

- INTERIORS

- At a glance

- Zoom

We asked Christophe Bruneau (Executive Vice President and General Manager of Safran Aircraft Engines’ Military Engine Division), Jocelyn Escourrou (FCAS program director) and Jérôme Bonini (Vice President, R&T at Safran Aircraft Engines) to share their insights about the latest developments on this major program, which will bolster Safran’s independence in military technologies.

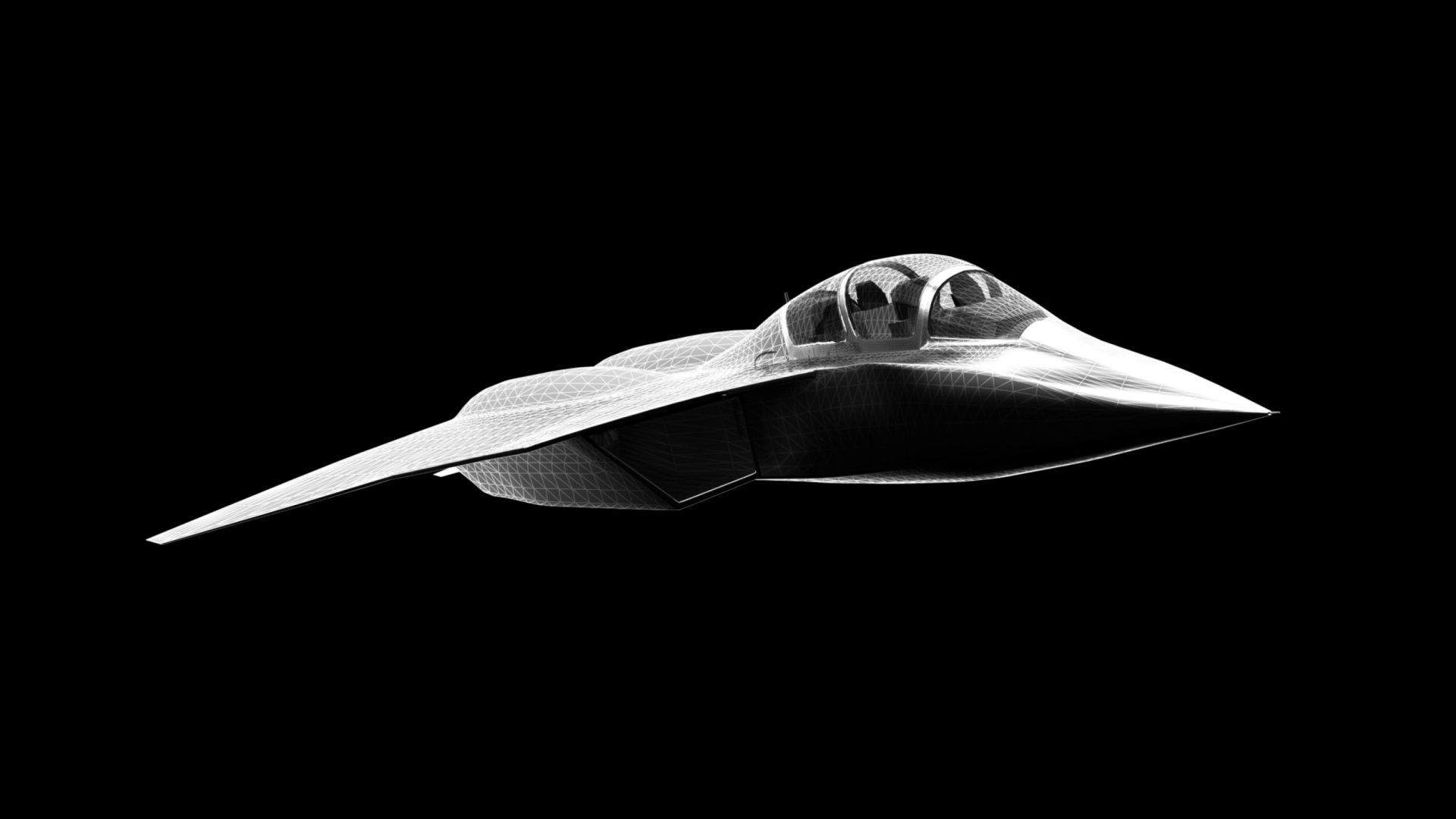

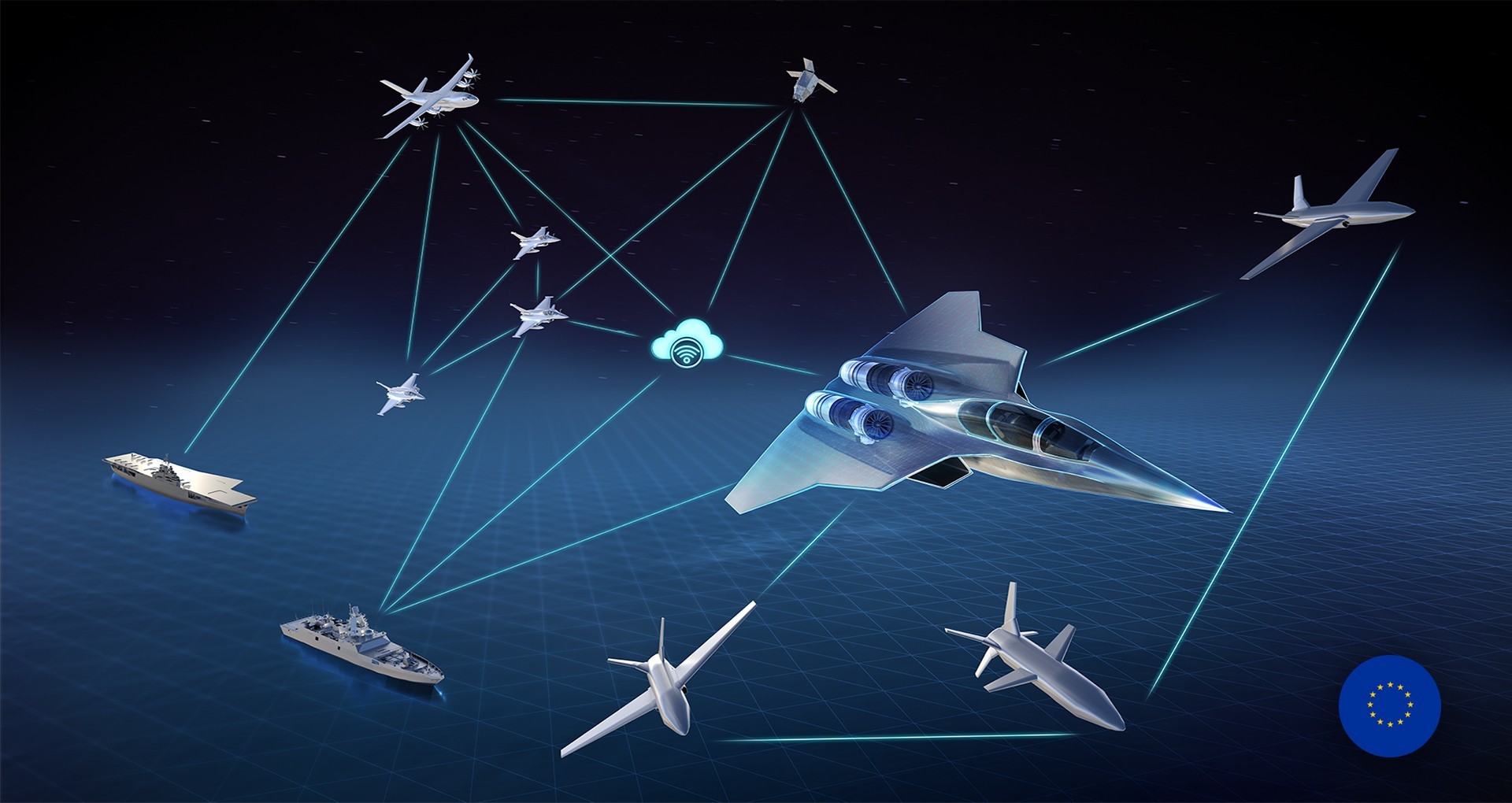

FCAS was launched by France and Germany in July 2017, with Spain joining the team in June 2019. It entails the development of an all-European combat air system that will meet tomorrow’s operational and sovereignty challenges. The program is an ambitious technological and industrial challenge, including in particular the development of a crewed and stealthy combat aircraft, the New Generation Fighter, or NGF. Powered by two state-of-the-art engines, the NGF will gradually take over from both the Rafale and the Eurofighter.

A highly strategic program for Europe… and Safran

Christophe Bruneau

“The FCAS program is a cornerstone of European defense. It will structure the French and European defense industry and ensure its viability going forward, since FCAS represents a large-scale technological challenge.”

Safran Aircraft Engines is in charge of the NFG engine’s design and integration, as well as its hot section (core), via the EUMET joint venture. A lot is at stake for Safran Aircraft Engines in the development of a new-generation fighter engine, in terms of maintaining and developing technologies and skills to strengthen our status as a major engine manufacturer and the European leader in military aircraft propulsion. As Christophe Bruneau says, “It’s also important to remember that technological progress in military engines has always driven progress in commercial aviation and helped develop higher-performance engines and aircraft with improved range and fuel consumption.”

Several Safran companies are already part of the FCAS roadmap, including Safran Tech and Safran Ceramics, working closely with Safran Aircraft Engines to develop the NGF engine’s hot section. Others are also well positioned as candidates for FCAS contracts, including Safran Landing Systems, Safran Electronics & Defense, Safran Electrical & Power, Safran Power Units and Safran Aerosystems, counting on their long track record as supplier to a number of European defense programs.

A new program phase takes shape

The announcement of funding for the NGF engine’s R&T 1B phase on December 15, 2022 marks a decisive step forward in the FCAS program.

Program director Jocelyn Escourrou explains: “This announcement confirms our government customers’ trust in us. It also reflects the importance of the R&T work needed in military aircraft propulsion and Safran Aircraft Engines’ position as the technical leader in this joint European program. With this major contract, we’re undertaking concept validation and technology development work that will last through mid-2026. We must now rise to the challenge of ramping up resources and ensuring effective cooperation with our partners MTU Aero Engines and ITP Aero. This program is an unprecedented opportunity and a real source of pride for Safran.”

Focus on engine-airframe integration

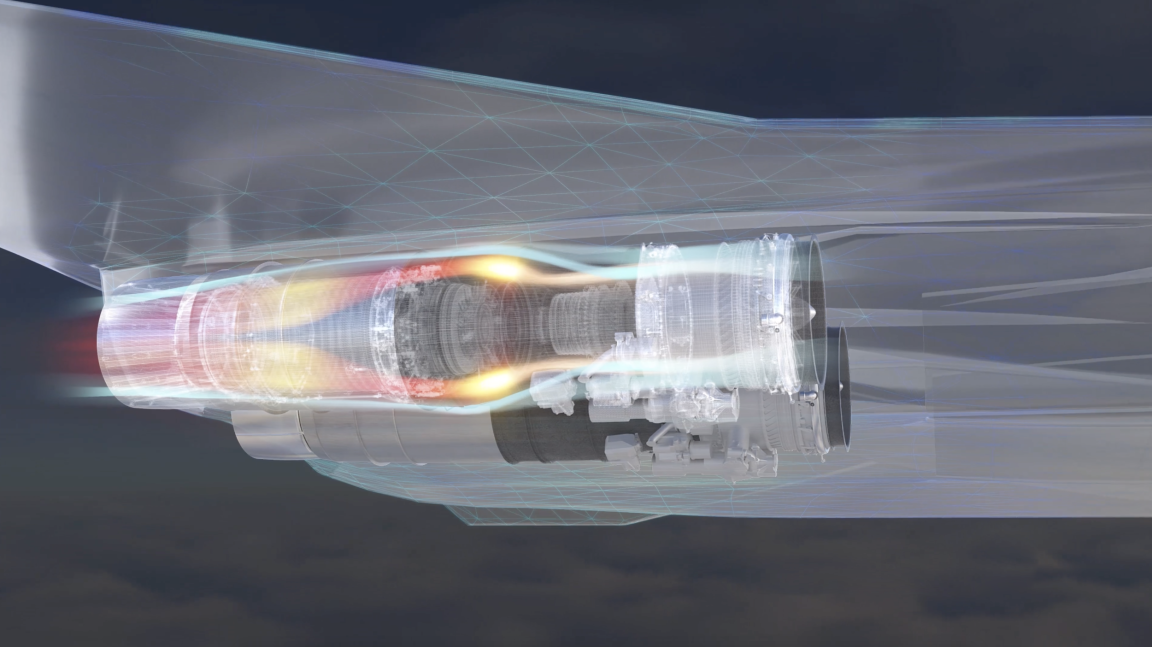

This latest phase signals the start of our work with Dassault Aviation on engine-airframe integration. In a modern fighter, the engine and airframe are so intimately intertwined that they have to be co-designed, including sizing, performance, mission capabilities, etc. The engine-maker’s aim is to develop the best engine for the best aircraft, which implies a measured tradeoff between technical performance (thrust, weight, fuel burn, stealth) and manufacturing and support requirements.

Jérôme Bonini

“To increase engine thrust while retaining a compact design, we’re going to increase the high-pressure turbine’s inlet temperature to a level that surpasses the capacity of current materials. Meeting this objective will require a quantum leap in technology, leading to innovations in single-crystal materials, powder metallurgy, cooling systems and ceramic matrix composites.”

Safran Aircraft Engines and partners are also looking into other technologies, such as hybrid and variable cycle designs, supercruise capacity and thrust vectoring, which could be incorporated into the engine depending on its final technical specifications.

Upcoming program milestones

Shortly before the planned end of the current R&T 1B phase, phase 2 of the program will be launched in mid-2025. Lasting a little more than three years, this next phase will continue to demonstrate the technologies developed for the program. It should also lead to the first flight of an NGF demonstrator by the end of the decade, powered by the M88 engine used on Dassault Aviation’s Rafale fighter. The demonstrator’s flight tests will pave the way for the development of the NGF, with entry into service towards 2040.

Systems for the Future Combat Air System

The FCAS is in fact a “system of systems”, built on nine technology pillars and coordinated by an industry champion acting as prime contractor. It comprises the New Generation Fighter with its new engine, along with support drones, forming a connected weapon system within a combat cloud. The other four pillars concern simulation, sensors, stealth and a joint work environment.

Prime contractor: Dassault Aviation

Lead partner: Airbus

Prime contractor: EUMET, a 50/50 joint company between Safran Aircraft Engines and MTU Aero Engines

Lead partner: ITP Aero

Involved in development:

Safran Tech

Safran Ceramics

Prime contractor: Airbus

Main partners: MBDA and Satnus

Prime contractor: Airbus

Main partners: Thales and Indra Sistemas