“By the hour” maintenance contracts: the new benchmark

The maintenance, repair and overhaul (MRO) of CFM56 and LEAP engines, already a solid business segment at Safran Aircraft Engines, will continue its strong growth in 2022 and beyond.

- Snapshots

- Best practices

- Perspective

- At a glance

n light of this, there are two major challenges ahead: efficiently manage “by the hour” service contracts for the LEAP, a key to the profitability of our aftersales business; and strengthen ongoing efforts to achieve excellence in terms of managing and reducing LEAP® maintenance costs. We asked François Planaud, head of the Services and MRO Division at Aircraft Engines, to share his insights, and take a closer look at the Squirrel line at our Châtellerault plant, a good example of the performance potential of MRO 4.0.

François Planaud explains how the business model is evolving in the commercial airplane engine MRO market: “The change in the aftersales market business model, along with economic, industrial and customer satisfaction objectives, is a pivotal part of our operations. For everybody in the division, they are both ambitious and highly motivating challenges, and a real source of competitiveness and innovation.”

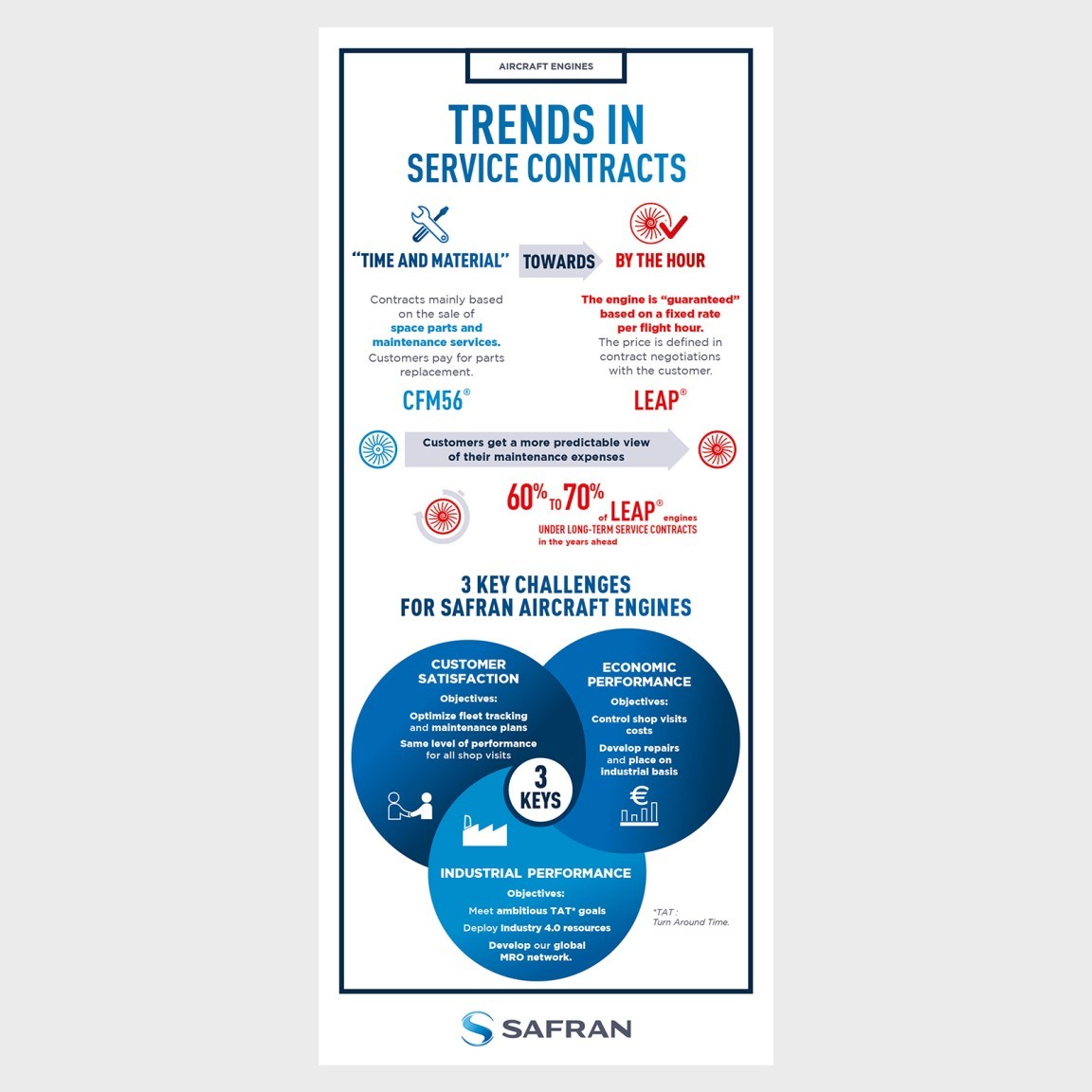

From a CFM56 MRO model known as “Time and Material”, based on the sale of spare parts and maintenance operations, with the LEAP we’re switching to a majority of fixed, long-term contracts billed per flight hour, also known as Rate per Flight Hour, or RPFH. In these long-term contracts, covering 12 years on average, the fixed price per flight-hour is established with the customer from the outset. Contracts cover shop maintenance for engines of course, but often include other services, such as the supply of spare engines and engineering services. The aim is to give airlines a clearer view of their maintenance expenditures over time. Right from when the LEAP® first entered service, this type of contract gradually became the new benchmark. And in the coming years, from 60% to 70% of all LEAP engines should be covered by long-term contracts. For us, the challenge is to keep reducing maintenance costs, while also overseeing the flightworthiness of the equipment we maintain, to ensure customer satisfaction

What factors determine the profitability of LEAP service contracts?

“These factors are very diverse, including technical, industrial and commercial actions, and we apply them through an industrial type organization and contract management processes,” notes François Planaud. “The first objective, also a key to customer satisfaction, is optimizing fleet monitoring and maintenance schedules. By calling on digital tools (health monitoring, remote diagnostics, algorithms, etc.) and all the data available, we can forecast trends and events, and thus custom-tailor the maintenance plan for each engine.

“Keeping shop visit costs under control is crucial. For the LEAP, we rolled out a large-scale plan to develop repairs and place them on a more industrial basis. Our objective is clear: we want to deploy all the repairs needed to achieve cost targets, right from the first major shop visits, scheduled to start in 2024.

“The industrial challenge is equally daunting: we must continue to boost the development of our MRO capabilities to deal with the expected ramp-up in LEAP shop visits and improve our industrial performance and regularity to meet ambitious turnaround time (TAT) goals, a key indicator of industrial efficiency that will further ensure customer satisfaction. All of our facilities have initiated modernization and transformation projects to increase operational capacity and efficiency. We’re also looking into the creation of new entities. The deployment of Manufacturing 4.0 standards is an integral part of our action plans, as shown by the creation of the new Squirrel repair line at our Châtellerault plant.”

SQUIRREL: 4.0 repair facilities and a one-stop shop at Châtellerault

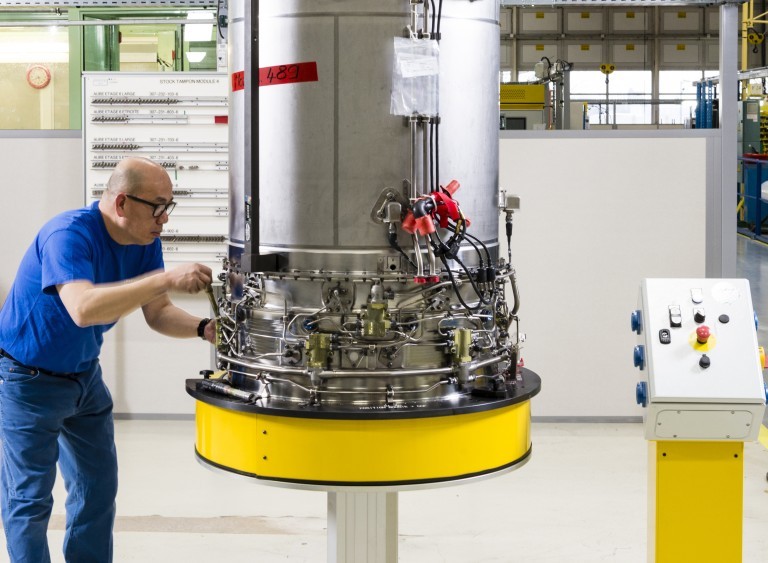

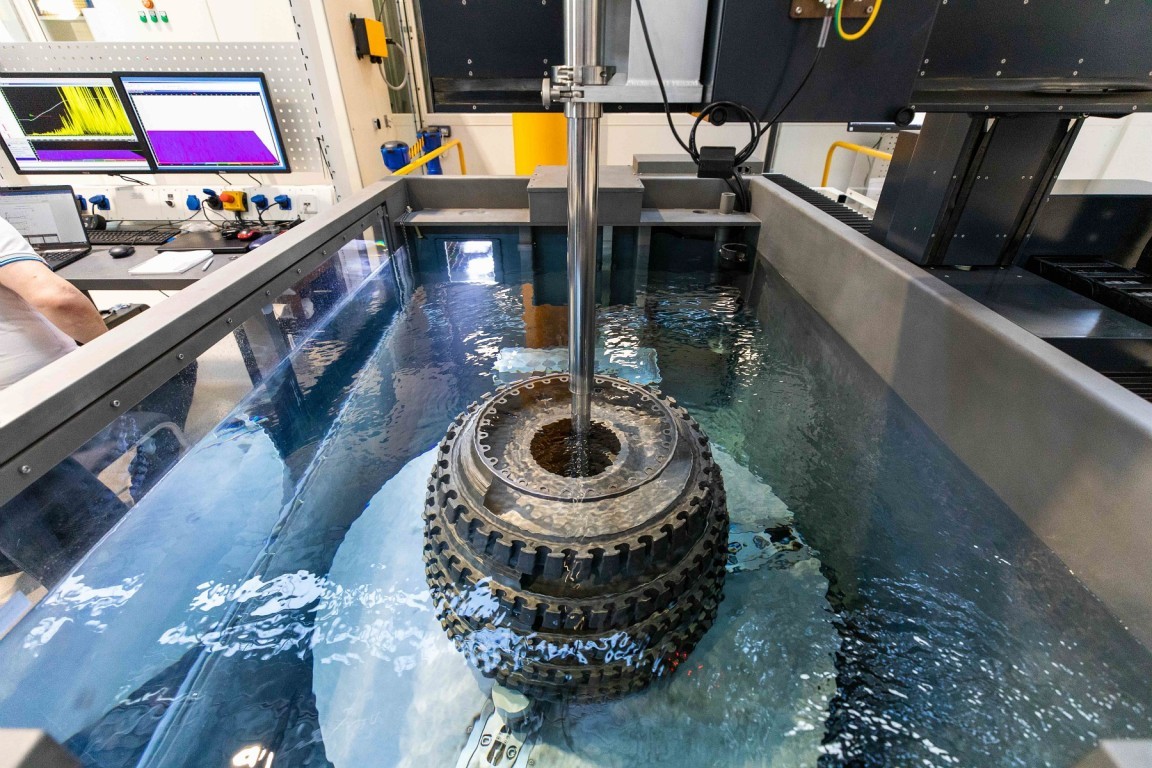

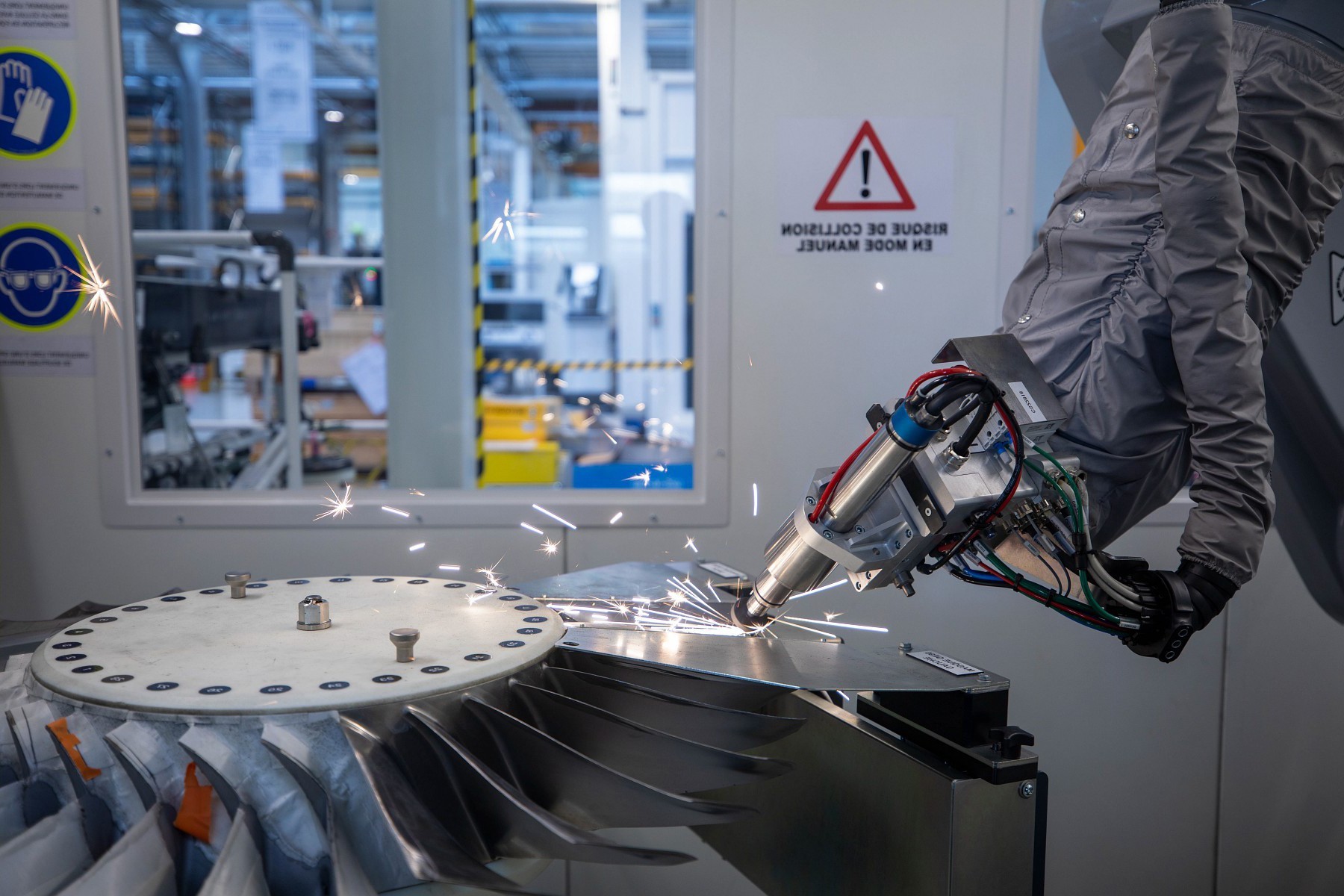

Self-guided carts to carry heavy parts, automated re-tapering using a machining robot, the non-destructive ultrasonic immersion testing method, automated operations control, etc. These are just a few of the manufacturing 4.0 tools featured on the new repair line for commercial engine rotating parts, dubbed Squirrel, which was opened in December 2021 at the Châtellerault plant.

Initially intended for the repair of components on larger turbofans (mainly the GE90), it will subsequently contribute to the ramp-up of LEAP® repairs. “By consolidating all these resources at a single facility, we’ve created a real ‘one-stop shop’ spanning the entire repair cycle,” explains Ludovic Molliex, head of repairs at the Services & MRO Division. “It’s a real advantage in meeting our cost and TAT objectives. The overall aim is to drastically reduce the time needed for parts repair, thus improving the dispatch reliability of the engines deployed by our airline customers. At the same time, it will help reduce the carbon footprint associated with transporting these parts.”

(1) Time and Material : facturation à la shop visit en fonction de la consommation de pièces de rechange, de réparations effectuées et du temps passé.

(2) Shop visit : visite en atelier.

(3) TAT : Turn Around Time, cycle de révision du moteur.