A new customer experience by Safran Helicopter Engines

As a pioneer in by-the-hour contracts, Safran Helicopter Engines continues to evolve its services strategy to better support its customers. Sébastien Jaulerry, EVP Support Services, tells us more about new solutions, innovations, digitalization and other transformations.

- Snapshots

- Best practices

- Perspective

- At a glance

We often distinguish between aftersales support and services. What do these activities involve?

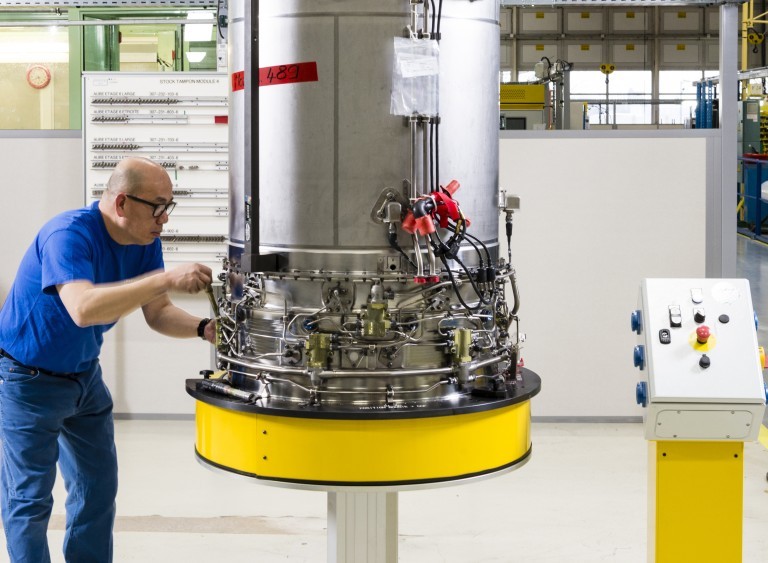

Sébastien Jaulerry: To be honest, there’s a lot of gray area. Put simply, you could say “support” refers to the standard aftersales offered by an engine manufacturer — repairs, maintenance, standard replacement, etc. — whereas “services” includes other à la carte services, which are billed on top. However, this distinction no longer meets the expectations of operators, who want complete, no-nonsense packages, with no surprises or surcharges. So, services need to be built into an overall customer support strategy. For this reason, we’re currently rolling out our “services to support” concept.

What’s at stake for Safran Helicopter Engines and your customers?

S. J.: For us, there are huge economic implications, because 70% of our revenue comes from support services. There’s also the “good business” aspect: if a customer’s pleased with the services we deliver, they’ll be more likely to buy our engines in the future. For operators, the main issues are flight safety and dispatch reliability.

“Customers want operational availability and lower cost of ownership.”

How are you meeting these expectations right now?

S. J.: For several years we’ve been offering by-the-hour contracts, which commits us in terms of engine dispatch reliability. Almost half our customers have chosen this solution — notably those operators flying the most hours or performing critical missions, like military operators or emergency medical services. Others have stayed with conventional time and material type contracts, which are billed on an event basis (maintenance, repair, etc.). In 2018, we launched our EngineLife® web portal, which gives 24/7 access to our digital services: tracking of engine repairs, parts ordering, technical documentation, engine health monitoring, remote video assistance, etc.

What else is in the pipeline?

S. J.: We’ll obviously keep innovating on the services front, for example with an electronic “health record” for our engines and new, more advanced health monitoring algorithms. We’re also keen to increase the number of by-the-hour contracts, which is the only win-win alternative. Customers benefit from higher levels of engine reliability, while we maintain our business model. To achieve this, we’ll need to convince more customers to choose this kind of solution.

“Data’s at the heart of the services we’ll be offering in the future.”

How will you do that?

S. J.: By showing they can help cut the total cost of ownership of their engines. That’s where the digital transformation comes in. The idea is to use in-service engine data to limit maintenance to what’s actually needed, avoid unscheduled operations and make recommendations to ensure better use of engines and extend their life. So, we’ll be investing massively in data governance and making our argument on the basis of actual use cases, like our involvement with the H160M Guépard, developed for France’s HIL joint light helicopter program. Our contract with the French armed forces, working with Airbus as program prime contractor, includes access to engine flight data, which will help us optimize maintenance tasks. The contract is a real showcase and a chance to step up our role and demonstrate our legitimacy.